Anti-Corrosive Coil coating protect metal components against degradation due to moisture, salt spray, oxidation, or exposure to a variety of harmful chemicals. The two most common forms of coil corrosion are pitting and formicary. These two corrosive processes can occur in as little as a few weeks after installation. More typically, corrosion will begin appearing within a one-to-four-year period.

Key components of air conditioning systems such as heat exchangers, evaporator coils and condenser coils in external chillers, condensers and dry coolers are at continuous risk of corrosion due to weather conditions and pollution.

Heat exchangers and coils are made using aluminum, which is relatively corrosion resistant even without any type of coating. However, the harsh conditions in certain air conditioning applications often require additional protection, these include:

• Offshore applications

• Coastal applications

• Power plants

• Industrial environments

• Urban dense applications

• Any area to have high levels of airborne pollutants

There are many airborne substances and atmospheric influences that shorten the life of heat exchangers; these include corrosive salts, acids, bases, and/or other chemicals.

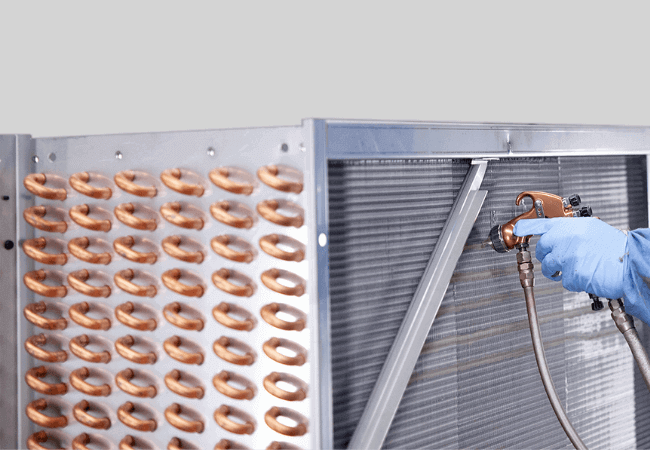

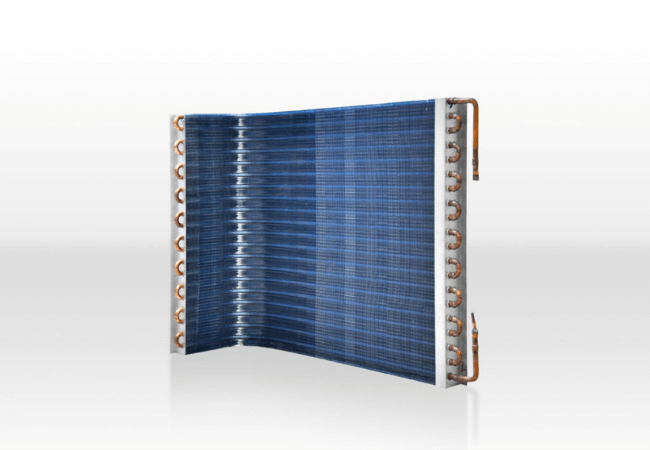

Airedale provides a long-lasting anti-corrosion treatment for heat exchangers. This preventative process seals off the heat exchanger from the environment, without affecting heat transfer and pressure drop.

The process can be applied to new units at our factory in Leeds as well as on-site via our Coil Protection service through our nationwide network of expert service engineers. It can also be applied to both Airedale’s and third-party manufacturer’s equipment on-site and can be applied to any type of heat exchanger/coil.

What our clients say about us