Emerald Cleaning offers HVAC duct cleaning across Qatar, providing professional air duct cleaning, dryer vent cleaning, and more to residential and commercial properties. Emerald Cleaning delivers top-quality results and has the highest standard of customer satisfaction in the industry. Our highly trained technicians have the skill and experience to tackle any residential and commercial HVAC ductwork or ventilation cleaning project.

Almost all air-based systems today use air ducts. Air ducts are required in almost all buildings, whether they are used for cooling or heating. You have likely seen large versions of these in commercial buildings that operate large HVAC systems with large air ducts running along the lines of the ceiling. These items are used extensively every day and, as a result, require maintenance to function properly. Emerald is the best residential HVAC duct cleaning company in Qatar.

Air ducts are a necessary component of practically any modern air-based system. Air ducts are required in practically all structures, whether for cooling or heating. Furthermore, because these systems are used daily, they require regular maintenance to perform properly. Residential duct cleaning services in Qatar are few in number and there are even fewer that you can trust.

Emerald Cleaning Services is a duct cleaning company that specializes in cleaning air ducts and vents. Regardless of size, dimension, or form, we provide sophisticated cleaning solutions for all sorts of ducting and HVAC systems. Our highly skilled residential duct cleaning staff is always examining and revising their cleaning processes in order to improve their quality. All work is done as quickly and quietly as possible to cause the least amount of disruption to you and your loved ones.

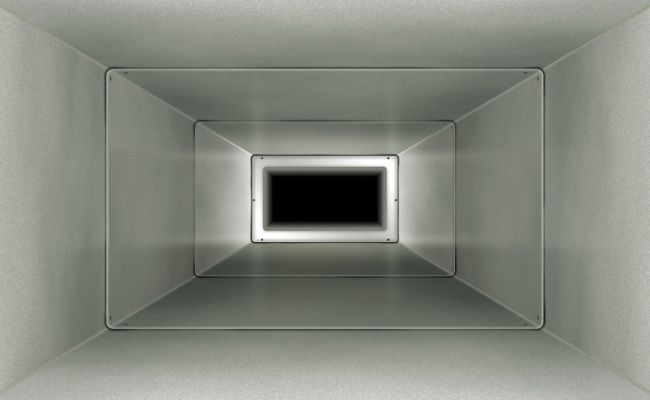

While many consumers have become more aware of how to maintain their systems in recent years, there is still room for improvement. For starters, even if you are meticulous about maintaining your air-based system, you will never notice the air ducts. These air ducts are located a little further inside, and they acquire a lot of dust and other filthy particles over time. This lowers the quality of the air produced. This is why professional residential duct cleaning in Qatar is such a crucial part of keeping these ducts in good working order. Even with basic professional cleaning, you’ll be surprised at how much dust and filth is removed. Your ducts’ interiors become a faint brownish color with time, although they should be a gleaming silver on the inside.

Contaminants pollute your air conditioner and also propel through the air every time you run your HVAC system.

Contaminants build harmful bacteria in your system, causing blockages that prevent sufficient airflow.

Over time, this can be the reason behind allergies, ill-health, and the cause asthmatic and other respiratory illnesses

Contaminates reduce your air conditioner’s airflow capacity to heat or cool the air, causing high heat loads on the fan motor.

Cleaning and sanitization of AC DUCT in accordance with SMACNA-NADCA ACR 2013 Standard using NADCA-certified technicians. This includes reviewing the filters, supply and return connected ducting, and using HEPA-filtered Roto brush–air and power-driven agitation equipment with EPA-approved chemicals. It also includes deep cleaning, vacuuming fogging, and sanitization of only reachable/accessible areas in-accordance with SMACNA standards.

Frequently Asked Questions

Our services are situated across Qatar and we cater to almost the whole area. Just give us a call to find out more 4435 2768. You can easily book an appointment and leave the cleaning up to us.

Duct cleaning can be done in a variety of ways and in different scenarios. Before the work begins, you will be given a price estimate based on the results of your checkup. Our staff will provide you with a detailed quote that explains why and where repairs/cleaning are required. You don’t have to pay anything up front.

While the possibilities of this happening are low, if we are unable to assist you for any reason, we will ensure that your issue is resolved. We take customer satisfaction very seriously and work hard to fix any problems that arise.

Residential duct cleaning services in Qatar are generally are required about every two years but this number vastly depends on various variables. For begin, the amount of dust collected is determined by your usage frequency, and the size of your room has an impact on the ducting. Regular checkups are usually a good idea to avoid severe problems in the future.

Choosing our services is the equivalent of choosing the best residential Duct Cleaning Services In Qatar. We have a team of trained specialists who are well equipped for the job and can easily guide you through the process. These are the things you can expect from us:

– Quality service

– No hidden costs whatsoever

– 100% experience backed services

– Punctual visits

– A detailed explanation of the problem

– Free additional air testing

What our clients say about us